Let’s dive in! Automotive diagnostics have come a long way, and modern OBD-II scan tools are game-changers for tackling air bag issues. Whether you’re a seasoned mechanic or a DIY car enthusiast, these tools are must-haves. They help you spot problems, read codes, and keep your vehicle’s safety systems in top shape. In this guide, we’ll walk you through using these tools step-by-step to ensure your air bags are ready when you need them most.

Key Takeaways to Get You Started

- Master the cool features of OBD-II scan tools for air bag diagnostics.

- Learn to pull and decode diagnostic trouble codes (DTCs) from the SRS system.

- Run targeted tests to pinpoint air bag glitches.

- Get the hang of clearing codes and resetting air bag modules.

- Track results like a pro to catch recurring issues early.

Getting Your Car Ready for a Scan

Before you plug in that scan tool, let’s prep your ride. First, hunt down the OBD-II port—it’s usually hiding under the dashboard or in the engine bay. A solid connection here is everything; it’s your lifeline to accurate data.

Next, check your battery. A weak one can mess up the whole process, so make sure it’s got enough juice. Oh, and grab your car’s make, model, and year too. This info helps the scan tool talk to your vehicle the right way.

| Preparation Step | Why It Matters |

|---|---|

| Locate OBD-II Port | Gets your scan tool connected securely. |

| Check Battery Condition | Keeps the scan running without a hitch. |

| Gather Vehicle Info | Makes sure the tool pulls the right data. |

Follow these steps, and you’re set for a smooth, spot-on diagnostic session!

Hooking Up Your Scan Tool the Right Way

Alright, let’s get that scan tool connected. You’ve got two options: wireless Bluetooth or a good old wired setup. Both work great—it just depends on what you’re comfy with.

Going Wireless with Bluetooth

For Bluetooth, pair your scan tool with the car’s computer. It’s super slick—no cables, easy movement, and smooth data flow. Just make sure the connection’s solid!

Plugging In with a Wired Connection

Prefer cables? Plug the tool straight into the OBD-II port under the dash. It’s rock-steady and delivers data without fuss. Perfect if you like things simple.

| Connection Type | Pros | Cons |

|---|---|---|

| Bluetooth |

|

|

| Wired OBD-II |

|

|

“Getting the scan tool hooked up right is the first step to nailing air bag diagnostics. It’s like giving your car a voice to tell you what’s wrong!”

Making Sense of Scan Tool Menus

Once you’re connected, it’s time to explore the scan tool’s menus. Think of it like navigating a smartphone—pretty straightforward once you get the hang of it.

Finding the Air Bag/SRS System

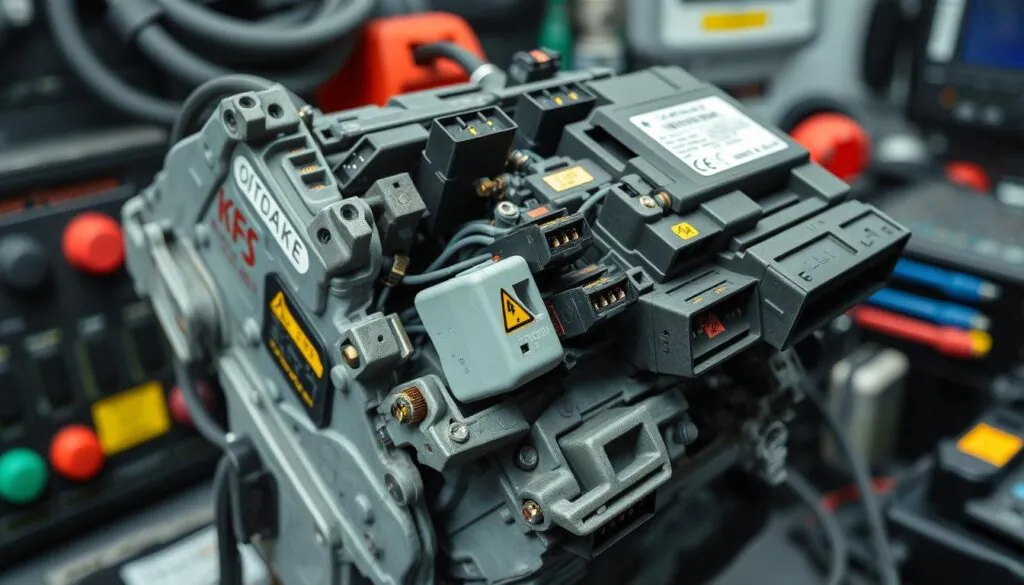

Dive into the menu and look for the air bag or SRS (Supplemental Restraint System) option. Tools like the ANCEL X7, with its big 10.1-inch touchscreen, make this a breeze. You’ll get detailed insights into the air bag system, plus extras like engine and transmission checks.

Reading the System Info

- The tool spills the beans—fault codes, system status, you name it.

- Understanding this is your ticket to spotting issues fast.

- With the ANCEL X7’s Active Test, you can even control parts of the system to dig deeper.

Master these menus, and you’ll be diagnosing like a pro in no time!

“The ANCEL X7’s menu is a total lifesaver. It’s so easy to use, and the details it gives me have stepped up my air bag game big time!” – Master Technician, ABC Automotive Repair

Cracking the Code: Understanding DTCs

Here’s where it gets fun—diagnostic trouble codes (DTCs) are like secret messages from your car. They tell you what’s up with the air bag system, and your scan tool’s the decoder.

What Do DTCs Mean?

Each code points to a specific issue—like a sensor glitch or wiring problem. Knowing what they mean helps you zero in on the fix. It’s like having a cheat sheet for repairs!

Focusing on the Big Ones

Not all codes are equal. Some scream “fix me now!”—think critical air bag faults. Tackle those first to keep your car safe. Ignoring them? Bad idea. You could end up with more damage or failed emissions tests.

With a solid grasp of DTCs, you’re ready to tackle air bag issues head-on. Safety first, right?

Running Tests Like a Detective

Scan tools aren’t just for reading codes—they let you play detective with system-specific tests. You can poke around the air bag system and see what’s working (or not).

Testing Air Bag Deployment

Ever wonder if your air bags will pop when they should? Deployment tests check that. They spot issues like faulty wiring or sensors, so you know everything’s good to go.

Checking Sensor Signals

Sensors are the eyes of the air bag system. The scan tool tests their responses—impact sensors, occupant sensors, all of ’em. If something’s off, you’ll know what to fix.

These tests are your secret weapon for keeping air bags reliable. You bet they make a difference!

Clearing Codes and Resetting the System

Fixed the problem? Awesome! Now, let’s clean up. Clearing codes and resetting modules wipes the slate clean and gets your air bag system back on track.

Wiping Out DTCs

Use the scan tool to erase those pesky codes. It clears the system’s memory, so old faults don’t haunt you. Double-check the big ones are resolved first, though!

Resetting Air Bag Modules

Resetting the modules brings everything back to factory settings. Follow the tool’s steps, and you’ll have a fresh, fully functional system ready for action.

Skipping this step might leave warning lights on or cause trouble later. Don’t risk it—reset and roll with confidence!

Keeping Tabs on Your Results

You’re not done yet—documenting your work is key. It’s like keeping a diary for your car’s air bag system, and it pays off big time.

Logging Every Detail

Jot down what you find—codes, fixes, everything. It helps you track progress and spot patterns. Plus, it’s gold for future checks.

Spotting Trouble Trends

Look at your notes over time. See the same issue popping up? That’s your cue to dig deeper and fix it for good. Smarter repairs, safer rides!

Common Air Bag Problems Scan Tools Catch

Air bags are lifesavers, but they’re not perfect. Scan tools shine at sniffing out the usual suspects. Let’s break down the big ones.

Faulty Sensors and Wiring

Sensors or wires acting up? Scan tools catch codes like B0090:11 (short to ground) or B0090:93 (no operation). They help you pinpoint and fix these gremlins fast.

| Code | What It Means |

|---|---|

| B0090:11 | Short to ground in a sensor circuit. |

| B0090:4A | Wrong part installed. |

| B0090:96 | Sensor’s toast—internal failure. |

“Fixing sensor and wiring issues right keeps your air bags ready for action. Safety’s non-negotiable!”

Control Module Mishaps

The air bag control module’s the boss of the system. If it’s glitchy—say, communication errors or hardware fails—scan tools spot it. Reprogram or replace, and you’re golden.

Seat Belt Pretensioner Troubles

Pretensioners tighten seat belts in a crash. Codes like 00654 or 00655 signal electrical or mechanical woes. Scan tools help you sort it out and keep safety tight.

Occupant Classification Glitches

The OCS figures out who’s in the car so air bags deploy right. Faulty sensors or wiring? Scan tools catch it, ensuring the system’s got your back.

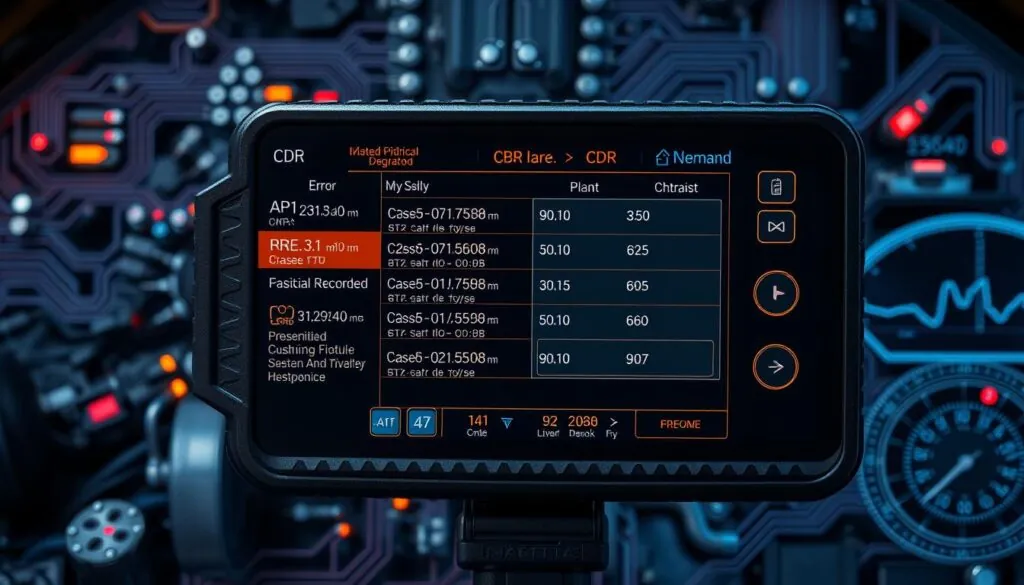

Crash Data Recorder Hiccups

CDRs log crash details—super handy for investigations. Errors from damage or software bugs? Scan tools dig in and fix ’em, keeping data legit.

SRS Warning Light Woes

That pesky SRS light won’t shut off? Scan tools decode why—maybe a clock spring’s busted or a sensor’s off. Fix it quick to trust the system again.

Air Bags Not Deploying After a Crash

If air bags don’t pop post-collision, something’s wrong. Scan tools check sensors, wiring, and more to get them firing on cue next time.

With your trusty scan tool, you’ve got the power to keep air bags—and your car—safe and sound. Ready to roll?